Interest in LNG-Powered Ships Fuel Gas Supply Systems Increasing

Published: October 14, 2021

Category: News

By Isabelle Simonsen

Position:

Interest in LNG-powered ships is continuing to increase and the current orderbook stands at more than 150 ships, latterly driven by a rise in larger containerships and car carrier ordering.

R. Stahl’s Business Development Manager, Ingo Emde, explained that just as LNG-powered ships are seeing increased interest, the focus has also turned to alternative drive types, known as fuel gas supply systems (FGSS).

FGSS provide a complete fuel gas handling system for LNG-fuelled ships, storing, pressurising, and vaporising LNG ready to be supplied as a fuel gas. The system includes an LNG storage tank, an LNG process system, a bunker system, plus a control & safety system. These core components are backed up by a sophisticated network of evaporators, compressors, pumps, and heat exchangers with a subsequent need for data on temperature, pressure, and flow values (and their position) to be fed into the ship’s control and alarm control monitoring systems (ACMS). Yet, FGSS installations also come with several challenges, due to the high volatility and flammability of the conveyed gas, Emde said.

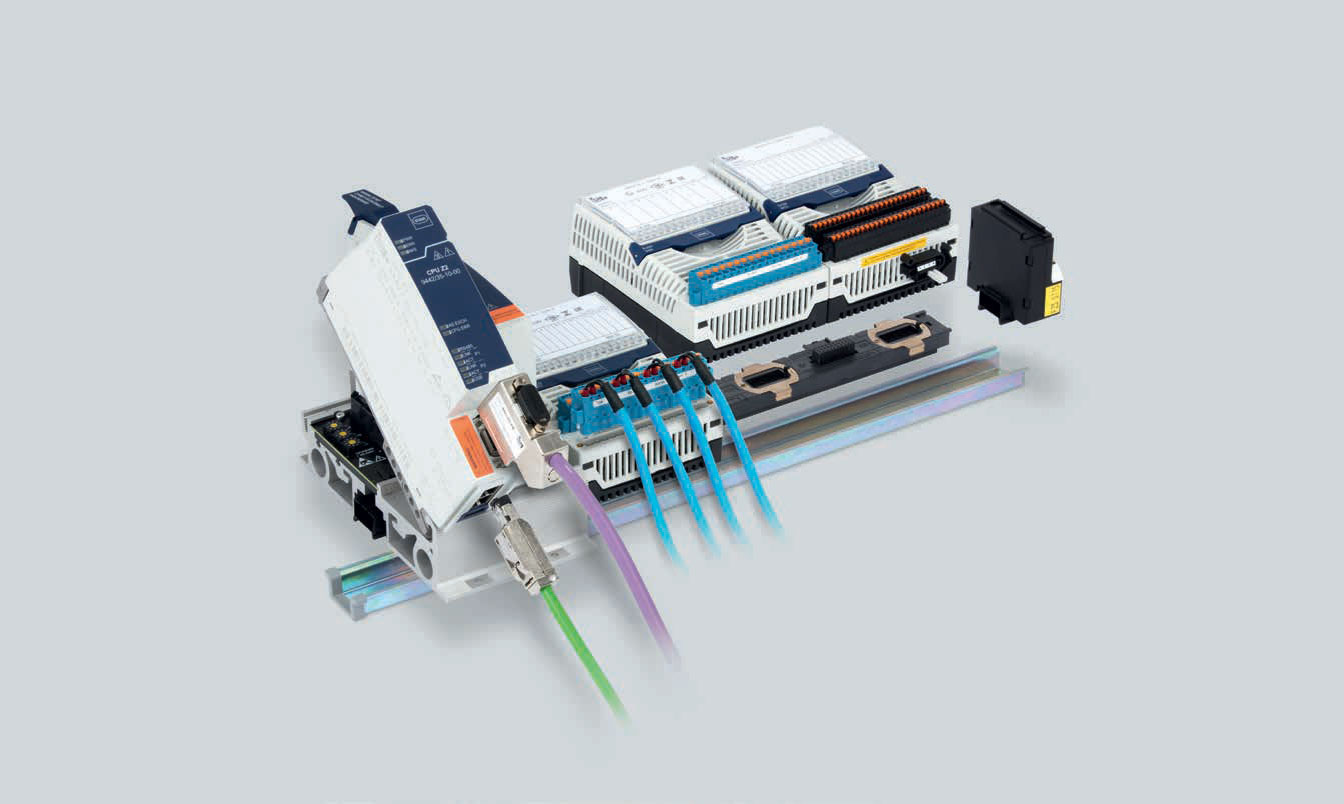

Retrofitting ships powered by heavy fuel oil to enable them to use FGSS will mean additional hazardous areas on board requiring the integration of explosion protected Input/Output (I/O) and display systems within the ship’s control system and on board alarm monitoring. Other challenges with deploying a FGSS include the need to seamlessly transmit the sensor data from hazardous zones to the ship’s control centre; the need for resilience and reduced maintenance; and the importance of a flexible system that can be scaled up and down accordingly. Today, many customers are requesting an FGSS connection that works with remote I/O systems for quality assurance and safety reasons and that also meets their data transfer, resilience, and flexibility requirements. It’s with these issues in mind that R. Stahl, a manufacturer of explosion protection and electrical products, which has been implementing remote I/O installations on ships and offshore platforms for over 30 years, has developed a solution for intrinsically safe sensor/ actuator networking in hazardous systems, such as FGSS. This solution is the IS1+ Remote I/O (Input/Output) system.

Hazardous areas

The system is designed for Hazardous Zone 1 – an area in which an explosive gas is likely to occur in normal operations – and is particularly suited to FGSS, due to the additional hazardous areas on board, Emde said. The control I/O devices surrounding the FGSS use multi-mode fibre optics for data transmission, enabling signals from hazardous areas to be connected to the distributed control system via PROFIBUS DP, Modbus RTU or Ethernet Modbus TCP, EtherNet/IP and PROFINET. Due to the low-power technology designed specifically for the IS1+ I/O level, the modules are also suitable for an extended temperature range between -40 deg C and +75 deg C and reach a service life of 15 years. Moreover, there is increased flexibility for the end user with the option to expand the installation at any time using the plug-and-play principle.

This solution has already been tried and tested on several hundred LNGCs and other oil & gas applications with regular orders for remote I/O solutions for LNGCs and FSRU’s that are operating worldwide under the most adverse environmental conditions. In South Korea, for example, the shipyards are seeing increasing demand for LNG-powered ships and many shipbuilders have opted for R. Stahl’s remote I/O system for sensor data transmission from the FGSS to command levels and ACMS systems. Over the past year, two of the largest shipyards and heavy engineering companies in South Korea have approached the company to adjust the specifications of existing ship control systems and the FGSS connection for use with R. Stahl products.

Yet the question remains – will the LNG ready vessels being ordered prove too expensive to retrofit in the long term? While the type of ship and the speed of the wider gas infrastructure will determine when the retrofitting and installation of LNG drives will see a return on investment (ROI), current model calculations show that gas drives on ships will offer an ROI after an average of five years, based on strict environmental requirements, the price of maritime diesel and decreasing costs of LNG supply. In addition, effective FGSS retrofitting and operation in hazardous areas will be a crucial element to any retrofits. They will also continue to be increasingly important over the next few years as more LNG-fuelled ships become operational with the need to integrate explosion protected I/O and display systems, Emde concluded.

Credit: LNG Journal

More news